How Low-Code/No-Code Platforms Are Revolutionizing Manufacturing in the IoT Era

The convergence of low-code/no-code structures and the Internet of Things (IoT) is ushering in a brand-new era of innovation for producers. As the industrial landscape evolves, these structures provide manufacturers the possibility to include IoT without the complexities traditionally related to it. This article explores how low-code/no-code systems are remodeling the manufacturing region, allowing fast adoption of IoT answers, and using efficiency, growth, and competitiveness.

Also see: tech news latest: AI and Journalism: Associated Press Issues New Guidelines

Also see: tech news latest: AI and Journalism: Associated Press Issues New Guidelines

Understanding Low-Code/No-Code Platforms

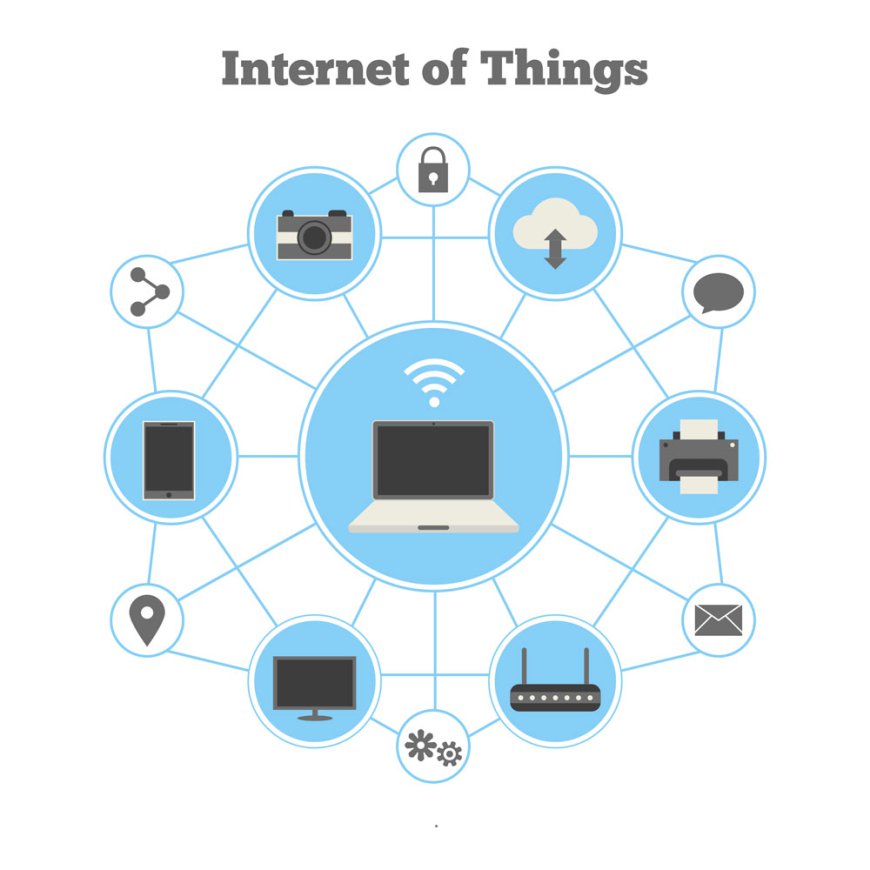

Low-code/no-code systems empower individuals with various technical know-how to create packages and software solutions without the want for massive coding understanding. These platforms offer a visual interface that permits customers to pull and drop pre-built components, which are then mechanically integrated and performed. This democratization of app development has made it less difficult for non-builders to participate in developing functional applications.The Role of IoT in Manufacturing

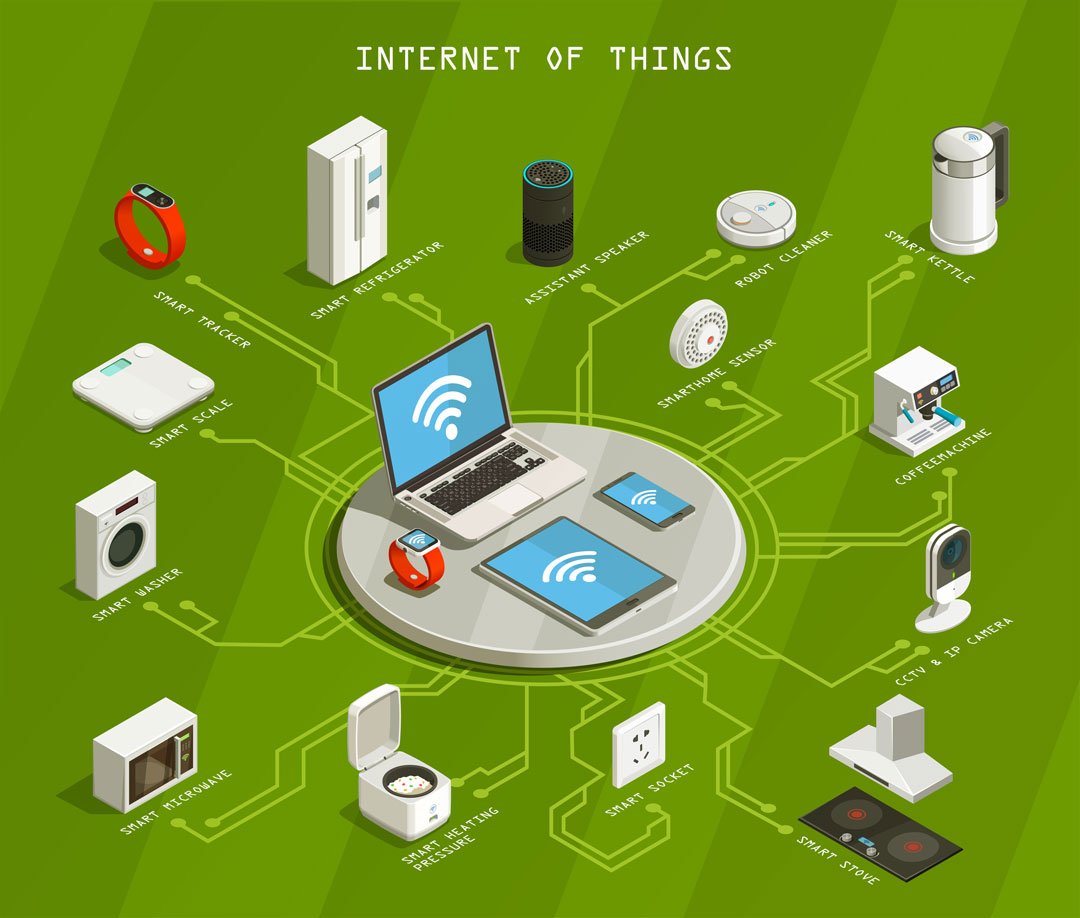

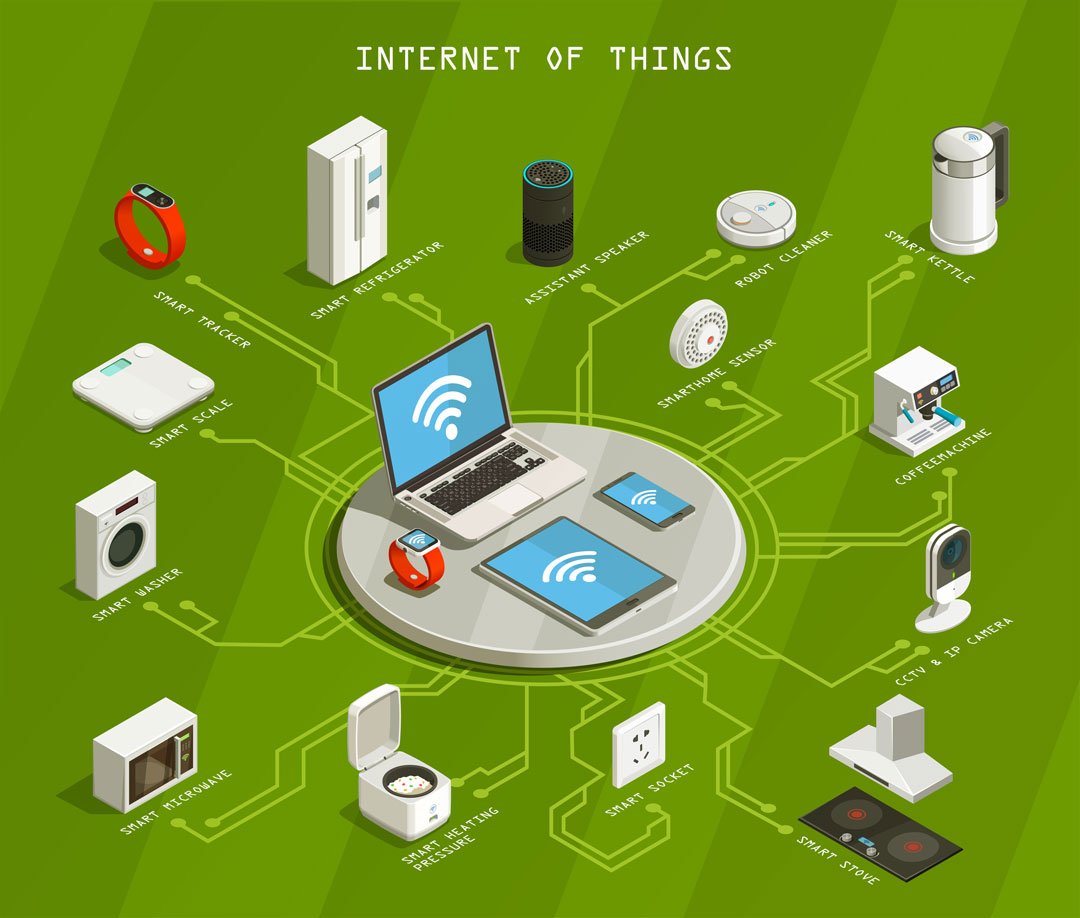

IoT entails connecting physical devices, machines, and systems to the net to collect and trade information. In manufacturing, IoT gives the capability to optimize strategies, monitor gadget fitness, enable predictive protection, enhance supply chain control, and create new revenue streams thru progressive commercial enterprise models.The Synergy of Low-Code/No-Code and IoT

1. Accelerated Development: Traditional IoT implementations frequently require giant coding and improvement time. Low-code/no-code structures substantially speed up the technique, permitting manufacturers to quickly construct and deploy IoT programs. 2. Cross-Functional Collaboration: These systems facilitate collaboration among IT and operations groups. Both technical and non-technical personnel can make a contribution to the creation of Internet of Things solutions, resulting in nicely-rounded and powerful applications. 3. Flexibility and Agility: As manufacturing methods evolve, the potential to swiftly alter and adapt IoT packages becomes vital. Low-code/no-code structures allow short changes without the want for widespread re-coding. 4. Resource Optimization: Manufacturers can make the maximum of their current resources by constructing IoT packages that enhance productivity, lessen downtime, and improve asset utilization. Also see: tech news latest: AI and Journalism: Associated Press Issues New Guidelines

Also see: tech news latest: AI and Journalism: Associated Press Issues New Guidelines